If you drive your vehicle for a prolonged period, it will undoubtedly have difficulties with the engine and other internal components. The most typical problems include the car severely shaking, the machine not starting, or the engine unexpectedly shutting down.

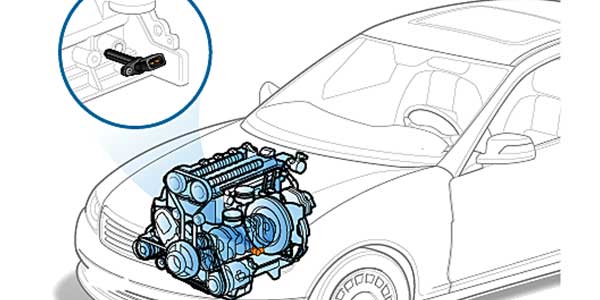

The crankshaft position sensor is an electronic sensor that measures the crankshaft’s position. It is critical, and as such, it should be kept in good working order.

The crankshaft position sensor loses out over time, causing the vehicle to come to a stop in the middle of the highway. As a result, the crankshaft position sensor must be repaired. In this comprehensive tutorial, we will look at whether it is possible to temporarily repair the crankshaft position sensor.

In short, there is no temporary fix for crankshaft position sensors; they must be in 100% functioning order, so to fix is to replace them as soon as possible, although there are a few simple fixes that allow the driver to take their car to a nearby repair shop if he is lucky.

Let’s get into what are the symptoms of a bad crankshaft position sensor

Without the proper knowledge, a driver can’t identify the exact issue that happened to a car, therefore I prefer to first explain the symptoms that directly relate to a bad crankshaft position sensor problem.

Here are the following:

| Crankshaft Sensor | Symptoms |

| Check Engine Light | The engine will not run properly if the engine control unit does not receive speed and crankshaft position data. If your car’s crankshaft position sensor is not operating properly, the “check engine” light will appear on the dashboard. This might be the first indication that the CKP sensor is malfunctioning. A bright “check engine light” might be triggered by a faulty crank sensor or by other factors. A crank sensor issue is characterized by the “check engine light flashing” and “vehicle rocking.” You may also use the OBD-II to diagnose the issue. |

| Engine Shudder | The engine has been fine-tuned to function in a coordinated manner with extremely tiny vibrations. When the crankshaft position sensor fails, the engine loses sync and begins to tremble, shake, and even stall. Mechanical vibrations are a major issue for any equipment, particularly the engine. They can cause greater component wear and damage, thus operating the vehicle under these conditions is not recommended. |

| Misfire | Misfiring happens when the ECU does not get information from the CKP sensor about the piston position and crankshaft speed. In addition, misfiring is an indirect cause of engine shutdown or vibration. |

| The Engine Rapidly Stops | A faulty crankshaft position sensor can also cause your engine to abruptly cease operating and your vehicle to come to a halt in the middle of the road. The ECU modifies the fueling time to guarantee that the engine does not run out of gasoline. If the CKP sensor is not serviced in a timely manner, this unexpected engine stop will become more often. |

| The Engine Is Suddenly Hard To Accelerate | That being said, if the crankshaft position sensor fails, the ECU will be unable to control the engine precisely as it should. This issue will give you discomfort since the vehicle does not have the energy to accelerate as quickly as you would want. |

| Impossible To Start the Car | If there are issues with the engine, ECU, or CKP sensor, starting the car becomes more difficult. It is critical to resolving the issues as soon as possible, since the longer the engine runs, the less likely it is to start. |

What Causes Crankshaft Sensor Position to Go Bad?

The crankshaft position sensor is a precise instrument, it must be in top working order to provide an accurate result. Without proper crankshaft sensor data, the engine may indicate a variety of issues.

| Crankshaft Sensor | Causes |

| Wheel and Pin Damage | The magnetic pulses produced by a toothed wheel or a series of pins are measured by the sensor. If any of the wheel’s teeth or pins are damaged, snapped off, or worn down, the pulse pattern will be disrupted. That implies the crankshaft sensor will be “confused” since it is obtaining an inaccurate reading of the crankshaft’s speed. |

| Magnetic Problems | The magnet may attract metal shavings produced by friction in the engine. If the shavings become stuck to the sensor or the wheel, the sensor’s readings will be thrown off. They might also begin to connect the sensor and the wheel. The sensor is meant to monitor the motions of the wheel at a specific distance, therefore bridging throws the results off by bringing them closer together.\ |

| Circuit and Wiring Problems | A sensor with a short circuit or an open circuit will fail to provide a reading to the ECU. If the cables burn out, the sensor may not get power for the electromagnet or may not send a signal to the ECU. |

How to Temporary Fix for Crankshaft Position Sensor?

It is correct that there is no temporary patch for the crankshaft position sensor. When the sensor fails, the only option is to replace it.

If your car suddenly stops on the road and there is no repair shop nearby, these ways can temporarily fix the issue and get you to a repair shop.

But, please understand, that these ways do not promise that your vehicle will be operational again; they are similar to the ventilation approach, which does not guarantee a positive outcome.

| Problem | Possible Solution Before taking into an Expert | Possible outcome |

| Engine Shudder | Restart the engine: You should pull over to the side of the road. Stopping the vehicle, shutting off the engine, waiting for the engine to cool, and then restarting your engine can help reduce shock in your vehicle. | High Likely |

| The Engine Rapidly Stops | Filling up fuel: If the vehicle suddenly stops because the ECU does not give enough gasoline to the cylinder, you may fix it by refueling it. | High Likely |

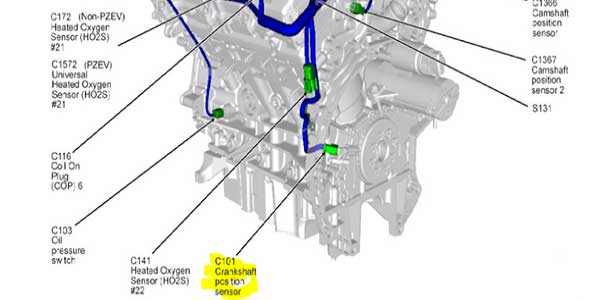

| Impossible To Start the Car | Disconnect the CKP sensor: If your car won’t start from the ground up, try unplugging the crank sensor. First, you must locate the CKP sensor according to the instructions (near the camshaft). Then you disconnect the CKP sensor connector and restart the vehicle. If you’re lucky, the car will start using factory mapping. | Least Likely |

| Misfire | Except for replacement, you cannot resolve this issue on your own. | Unlikely |

How to Replace the Crankshaft Position Sensor?

The crankshaft position sensor is held in place by a single bolt or screw. This makes it simple to modify. Disconnect the power plug from the bolt and take the old sensor out.

The most difficult element of the process is locating the sensor, which might be situated deep within the engine compartment. Each vehicle is unique, however, the sensor is often situated around the flywheel between the engine and transmission.

How Do You Test A Crankshaft Position Sensor?

A test lamp is required to test the crankshaft position sensor. There are two types of crankshaft sensors: one for 2-wire and one for 3- wire. Each model has a different testing process.

How Do You Test The 2-Wire Crankshaft Position Sensor?

- Unplug the crankshaft position sensor.

- Connect the positive battery terminal to the test light.

- Turn the ignition to “On.”

- Rapidly and repeatedly tap the sensor terminals.

- If you hear the spark plug click when you do this, the sensor is operating.

How Do You Test The 3-Wire Crankshaft Position Sensor?

- Unplug the crankshaft position sensor.

- Connect the ground battery terminal and the test bulb.

- Turn the ignition to “On.”

- To activate the signal terminal, press the center button.

- If you hear the spark plug click when you do this, the sensor is operating.

- These tests examine the vehicle’s reaction to the sensor signal. An injector pulse and a spark plug click accompany these tests.

Connect the test bulb to the positive terminal of a 2-wire sensor. For a 3-wire sensor, please connect it to the negative terminal.

You Might Want to read this:

Frequently Asked Questions:

How to Reset Crankshaft Position Sensor without Scanner?

- Engage the parking brake and secure the driving wheels. Check that the hood is closed.

- Start the engine and check that the engine coolant temperature is at least 158 degrees Fahrenheit (70 degrees C.)

- Deactivate the engine for at least 10 seconds.

- On your scanner, select the crankshaft position variation to learn the process.

- Ensure that the gearbox is in the Park position. Begin the engine.

- Apply the brakes and firmly press the pedal.

- Comply with the scanner’s instructions.

Remember:

That you will boost the engine speed to around 3000 RPM, 4000 RPM, or 5150 RPM. That is the variance learn fuel cutoff RPM (depending on the engine), and it is critical to release the throttle when the engine RPM begins to decrease due to the fuel cutoff entering into action. Failure to do so will result in the engine over-revving, perhaps causing engine damage.

How to Bypass Crank Position Sensor?

Under no circumstances may the crankshaft sensor be bypassed. The engine will not be able to function if the ECU does not know when to start the injection or ignition.

Even if you were successful in starting the engine, it would most likely misfire and stall. If you want to maintain the engine in excellent shape, don’t try to circumvent the crankshaft position sensor.

What Causes Crankshaft Sensor Damage?

The two most common sources of crankshaft position sensor damage are:

- Motor Overheating: This might cause the protective plastic to melt and destroy the sensor.

- Problematic circuitry: Voltage problems, loose wiring, and electrical system damage can all result in signal loss from the crank sensor to the ECU and vice versa.

What Scanner Can Relearn Crankshaft Position Sensor?

There are several good OBD2 scanners on the market that can relearn the crankshaft sensors.

- Launch CRT5011E

- Ancel V6 Pro

- Autel MaxiCOM MK808

What Is The Replacement Cost Of Crankshaft Position Sensor?

The cost to repair isn’t too high, it varies from location and model of the car, however, the average cost recorded was $200 to $250 dollar.

What is Crankshaft Sensor Position Code?

When the ECM is unable to detect crankshaft pulses, diagnostic issue code P0335 is shown. Without proper CKP measurements, your engine may indicate a variety of issues.

Is a crank sensor easy to fix?

In the majority of makes and types of cars, changing your crankshaft position sensor isn’t particularly challenging. The accurate ignition and fuel injection of your engine are greatly aided by the crankshaft position sensor. So you shouldn’t put off this repair.

Is crankshaft repairable?

A practical and appealing alternative that might result in significant savings is to repair a crankshaft rather than replace it. This Gard Insight examines the components and advantages.

Can you unplug crank sensor?

The sensor for the crankshaft. It can be found close to the timing cover or harmonic balancer on the engine. Remove the electrical connector from the sensor. After removing the mounting nuts, take the sensor out of its mounting.