You can test your fuel pressure regulator without a gauge by following the instructions I’ll provide you. This article on how to test a fuel pressure regulator without a gauge is for you if you suspect that your regulator may be faulty but do not have access to a gauge for testing.

Let’s start by outlining the purpose of a fuel pressure regulator. This mechanism controls how much fuel is required to an engine and, if it malfunctions, can cause a variety of problems like difficult starting, stalling, subpar performance, and fuel leaks. So, make sure that your fuel pressure regulator is operating properly is essential for proper engine functioning.

Why Would You Want To Check Fuel Pressure Without A Gauge?

A Schrader valve was frequently integrated into the fuel injection rail of older fuel-injected engines. This made it simple to connect a fuel pressure gauge to the engine and gauge fuel pressure.

Because engines operate at a considerably higher pressure now and a valve would introduce an extra weakness in the fuel rail, Schrader valves are no longer installed on the majority of engines.

Thankfully, modern cars come equipped with sensors that continuously check the fuel pressure throughout the fuel injectors. By adjusting the fuel supply rate, the ECU is able to maintain a constant fuel pressure whether the engine is running at idle or under load.

Fuel pressure at the injectors for common rail diesel engines can reach 2000 bar (29,000 PSI).

What Is The Correct Fuel Pressure Of An Engine?

Depending on the kind and size of the engine, modern gasoline fuel injection engines operate at a fuel pressure ranging from 40 PSI to 70 PSI.

How to Test a Fuel Pressure Regulator without a Gauge

Let’s get started by going over how to test a fuel pressure regulator without a gauge by using Two Methods.

How to check the fuel pressure regulator manually.

The following procedures can be used to test a fuel pressure regulator without a gauge:

1st METHODS:

1: Find the fuel pressure regulator

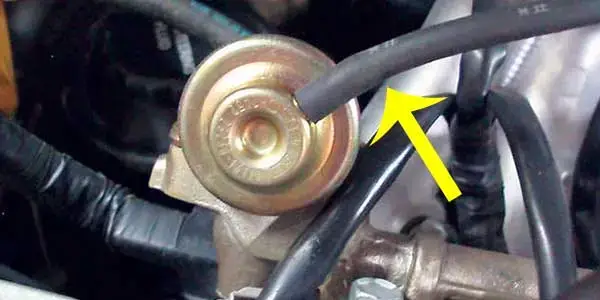

On the fuel rail, a metal pipe that runs along the top of your engine, is typically where you’ll find the fuel pressure regulator. It is connected to this rail by a little hose.

2: Remove the hose Pipe.

The fuel pressure regulator is connected to a little hose. Carefully remove this hose away from the regulator, taking care not to harm yourself or the device in the process.

3: Inspect the hose in step three.

After removing the hose, look for any evidence of fuel. If you see fuel flowing out, the regulator has to be replaced since it has a fault.

4: Start the engine

It’s time to start the car’s engine now. Allow it to warm up by running it for a while. If fuel is leaking from the hose end you severed from the fuel pressure regulator, the regulator is faulty and needs to be replaced.

Reconnect the hose to the fuel pressure regulator if petrol isn’t coming out of it, and then start the engine.

It’s time to start the engine and give it some time to warm up.

5: Monitor engine behavior.

See how it behaves while it runs. The following signs may point to a problem with the fuel pressure regulator if you observe any of them:

Rough idle, stalling, and hesitation when accelerating are just a few of the symptoms.

Other Symptoms:

1 Inefficient fuel economy

2 Exhaust black smoke.

6: Turn the engine off

Turn off the engine and watch what happens to make sure everything went as planned.

After observing how the engine behaves, turn it off.

7: Examine the fuel rail.

Check for any indications of fuel leaking on the fuel rail and in the vicinity of the fuel pressure regulator. If there is evidence, it shows that the regulator has a problem and has to be replaced.

8: Look for heavy smoke coming from the tailpipe.

Black smoke may be a sign that your fuel pressure regulator needs to be repaired if it is faulty.

2ND METHODS:

The easiest and safest method is a diagnostic code reader which is the simplest tool to use to check your car’s fuel pressure without a pressure gauge. As fuel system errors are present in all vehicles that accept OBD, any code reader should be able to handle the task.

1: Warm Up the Engine (If Possible)

Take your automobile for a quick 10-minute drive to warm up the engine if it would start. If there is a problem, cold engines use more gasoline, which can alter fuel pressure measurements.

2: Attach Your OBD-II Diagnostic Scanner to Your Car

As there are so many various kinds of scanners available, it would be hard for me to explain how to use each one in detail.

If the scanner is wired, locate the OBD-II socket on your car and plug it in before turning the key. Usually found beneath the dashboard, the socket could have some plastic trim covering it.

You’ll need to plug in the wireless OBD-II device and connect to it using the app if your wireless scanner links to an app on your tablet or smartphone.

3: Look For Stored OBD-II Trouble Codes

Checking for cached fault codes first will save you a ton of time before diving into particular fuel parameter readings.

An error code could be kept in the ECU memory if there is a fuel supply issue. The following list of frequently occurring OBD-II error codes can be saved when there are issues with the fuel system.

| OBD-II error code | Error Code Definition | Description of fuel error code |

| P0203 | Main fuel pump circuit failure | Indicates that there is a fuel pump electrical problem |

| P0170 | A fuel trim problems | Fuel trim has been discovered to be outside the acceptable range |

| P0171 | Method Too Lean | Not enough fuel or too much air |

| P0191 | System Too Rich Fuel Rail Pressure Sensor Circuit/Range Performance | Readings of the fuel rail pressure that vary |

| P0172 | Main fuel pump circuit failure | Oversupply of gasoline entering the injectors |

4: Verify the Real Fuel Pressure Statistics

The next step is to conduct an analysis of the fuel delivery system by measuring fuel pressure and fuel delivery rate if the stored fault codes don’t reveal any immediately apparent issues.

You’ll need an OBD-II code scanner with real-time engine data measurement to accomplish this. You will need to consult the guidebook for more information because not all diagnostic readers can perform this.

- Connect your diagnostic reader to the car, switch to engine DME diagnostic mode, and take a reading of the current engine parameters if your reader supports real-time data. Choose the gasoline distribution system (or a comparable) option after the reading is finished.

- This will enable you to keep an eye on a variety of various fuel system characteristics, including fuel rail pressure, measurements for each cylinder’s fuel injection timing, STFT (short-term fuel trim), and LTFT (long-term fuel trim).

- The fuel rail pressure set point should also be visible on the OBD scanner. You can use this figure to compare to the actual fuel pressure value since it represents the ideal fuel pressure on the fuel rail when the engine is running.

- Choose the option from the menu that most closely resembles the ‘actual (real-time) fuel pressure parameter’ to measure the actual fuel pressure while the engine is running.

- The reader should now show the fuel pressure as it is. Try revving the engine to 1500 rpm and holding it there for a few seconds, then try 2500-3000 rpm to see whether this remains constant under load.

There may not be a problem with the system’s overall pressure if the actual fuel pressure and the fuel pressure set point are the same, but there may still be a problem with the timing and volume of fuel delivered to the injectors.

Frequently Asked Questions:

Does seafoam clean fuel pressure regulator?

To clean and lubricate the entire fuel system, pour Sea Foam into your gasoline tank. To get rid of dangerous residues and deposits from fuel passages, intake valves, pistons, and chamber areas, it operates through carburetors and fuel injectors.