It is vital to replace a faulty camshaft position sensor before it completely fails and causes the engine to shut down.

There is a slight chance that a camshaft position sensor will malfunction. An unexpected event may be to blame. Age and general wear and tear could be other factors.

When the camshaft position sensor in your car is malfunctioning, you’ll likely get one of several codes, including P0011 or P0340.

If there is an issue with the wiring, the reluctor wheel for the camshaft position sensor, or if the replacement camshaft position sensor is incompatible or has a manufacturing flaw, the check engine light will continue to illuminate. The issue should be resolved by unplugging the battery for ten minutes or by using the OBD2 scanner to clear the codes.

What exactly is a camshaft position sensor, and what is it used for?

An automobile’s engine control module receives data regarding camshaft speed from a camshaft position sensor. The engine control module uses this information for various purposes, such as determining the engine’s optimal ignition and fuel injection timing.

The engine will not operate correctly if it does not get this data. Sometimes the sensor fails gradually over time. When initially implemented, the changes are subtle.

However, you may be wondering why, as time passes, the Vehicle can’t keep up as well as it once could. One possible cause is the camshaft position sensor.

The correct course of action is one that you alone determine. Getting your car fixed might be a hassle, even if it’s a camshaft position sensor. You have to weigh the costs of the repair against the risks of putting it off.

Be mindful of your well-being and financial resources while you decide how to proceed.

Don’t let something like a faulty camshaft position sensor ruin your engine or your day. A mechanic should check your car out if you’ve observed a decline in its driving qualities.

Reasons, why error codes persist even after the camshaft position sensor is replaced

You will usually get the P0340 and P0011 codes after replacing the camshaft position sensor. Here are common reasons why the error code stays:

- Removing error codes and relearn process isn’t done yet

- ECU is still coded with the old camshaft position sensor

- Bad installation or defective new camshaft position sensor

- Old O-ring isn’t removed from the camshaft sensor

- Problem with the Electric Circuit or Wiring.

- The Reluctor wheel is damaged or not functioning properly

- Wear and stretch on the timing chain and guide plates

- Faulty starter motor can cause the P0340 error code

- A faulty PCM

Symptoms of the Issue

1. Check The Engine Lights Up:

Suppose the Electronic Control Module detects that the camshaft position has been stuck due to any of the above causes. In that case, it will alert the onboard computer, triggering the check engine light to illuminate the dashboard.

2. Problem in starting the Vehicle:

If the camshaft becomes jammed, resetting it to its original position becomes an issue. Because of this problem, trying to start a car will be tough.

3. Reduced Fuel Economy:

A misreading of where the camshaft should result in increased fuel use. This will cause the Vehicle’s fuel efficiency to suffer.

4. Vehicle Rough Running and Stalling:

Suppose the camshaft isn’t in the right spot. In that case, the car’s electrical control unit may have trouble keeping everything in motion smoothly, leading to jerky acceleration or stalling. Because of the misalignment of the camshaft, the car will also stall.

5. Increase in Engine Emissions:

An increase in the Vehicle’s smoke output can be attributed to the timing mistake in the timing belt, which causes the camshaft to be out of phase with the fuel injection in the combustion chambers of different cylinders.

How to fix these codes to get rid of Replaced camshaft position sensor but still get the code?

As with many OBDII codes, you won’t find the fix for this one in the service manual. There might be more than one solution to a problem if more than one source is identified.

If you are familiar with how to clear the codes, or you have some kind of mechanical expertise then follow the below steps otherwise, must find your local machine repair shop to fix it as soon as possible.

So here are the fixes:

Recalibrate or Relearn the Sensor

Most of the time, if you don’t relearn the sensor after replacing it, the ECU may retain the previous sensor data and throw the error. In order to retrain the camshaft position sensor, perform these steps:

Step 1: Start the car, then attach an OBD2 scanning tool. Select your vehicle’s brand and model after turning on the scanning tool. Alternatively, choose Auto Detect. Your system will be automatically read. To produce better results, use the MaxiSys scanning tool.

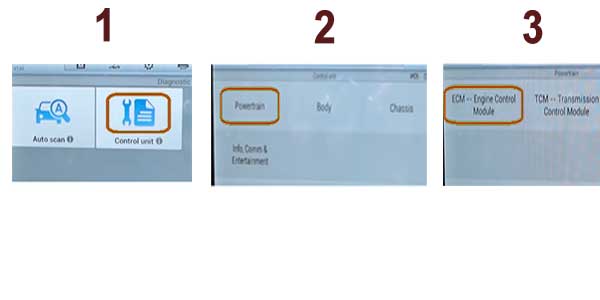

Step 2: Go to the Diagnosis option and follow the image order below.

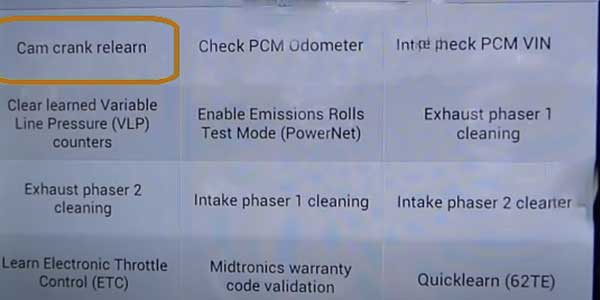

Step 3: Select the Cam crank relearn and “Special Function” options. You’ll be alerted in a new window when it’s time to retrain the sensor. Click Ok after reading it.

Step 4: The scanner will then request that you turn on the engine. Start the car. You must now wait until the engine coolant reaches the necessary temperature. Increase the vehicle’s speed to raise the inside temperature. The car will automatically perform the relearn procedure once it reaches the necessary temperature.

Inspect the O-rings

For the camshaft position sensor to operate properly, two O-rings are required. The camshaft position sensor is included with one, while the automobile manufacturer is responsible for the other.

An O-ring is included with the primary component of the camshaft position sensor. However, it appears to be a plastic ridge. Because of this, a lot of people attempt to put the old o-ring in the new one, which prevents correct installation and leaves a gap that leads to the problem.

You must take off the old O-ring before installing the new one. Afterward, you must use the original O-ring. Additionally, before using the O-ring, clean it.

Camshaft Position Sensor Wiring: Check and Repair

If relearning doesn’t resolve the problem and the code remains visible, the wiring that transmits signals to the problematic ECU is typically to blame. To resolve the problem, you must verify the wire harness for the camshaft position sensor.

Depending on the brand of the car, the wiring part will change. For an accurate examination, you must adhere to the following procedure:

Reviewing the wiring diagram: Typically, the camshaft sensor comes with three wires. They are available in a variety of hues, which may vary from vehicle to vehicle. The power supply, sensor signal, and sensor ground are all terms for the wiring.

Test the sensor power supply: First before moving on to other components. You must use a multimeter for this. Check the voltage after setting the multimeter to PIN 1. The power source for the circuit functions adequately when the voltage is approximately 5 amps.

Test for the sensor ground circuit using a multimeter: Verify the ground circuit’s continuity between the sensor wire harness and the ECM wiring harness. Make sure there has been continuity as well. If not, it signifies that the ground circuit is malfunctioning.

Test the sensor signal circuit for continuity between the cam sensor and the connection on the ECM harness. It must require continuity to work properly.

You must replace or repair any wires that are found to be damaged. If you lack technological expertise, seek for professional assistance.

Examine the Reluctor wheel

You must examine the Reluctor wheel if the aforementioned approach fails to resolve the problem. Many individuals neglect to tune the camshaft position sensor with the reluctor wheel after replacing it.

For this, you must correctly align the Reluctor wheel teeth with the camshaft position sensor. The majority of the vehicle’s sensors line up with the Reluctor wheel’s 20th tooth. Additionally, you must check the Reluctor wheel to determine whether any of the teeth are damaged or not.

Examine the starter motor

During ignition, the starting motor starts the engine, which then allows the rest of the process to happen. The signal flow from the camshaft position sensor to the ECU may be hampered if the starting motor has problems.

You must examine the starting motor for this. You must fix or replace it if you discover any defects on it.

Examine the timing chain

Professional mechanics have a variety of opinions on whether the timing chain is to blame for the problem code. However, you need to examine the timing chain if the error codes persist even after you’ve checked the aforementioned component.

If the timing chain is the cause of this issue, it must be replaced. It will cost you between $200 and $1,000, depending on the type of car.

Check the ECU

The camshaft position sensor sends a signal to the vehicle’s electronic control unit. You still receive the code even though the wire transmits the correct signal. It could happen as a result of an ECU issue.

You must determine whether the ECU correctly collects the signal and distributes it to the other components in order to do this. If the control unit doesn’t operate correctly, you must fix it to get rid of the error code.

Final thoughts

The electrical system is vulnerable to several potential problems. Possible causes include a broken reluctor wheel on the camshaft position sensor, bad wiring or connections, or a faulty camshaft position sensor.

You might want to see this:

- What Does Reduced Engine Power Mean?

- Temporary Fix for Crankshaft Position Sensor Easy Guide

- 5r110w Transmission Common Problems

Frequently Asked Questions:

What to do after replacing the camshaft position sensor?

Remove the codes from the computer and give it a test drive after you’ve swapped out the camshaft sensor. If the P0340 error message reappears, further investigation may reveal other issues.

What is the best camshaft sensor?

The Ford F4TZ-12K073-C CMP Sensor may be ideal for a trouble-free, robust engine operation. In addition, the engine won’t give you any trouble. Tin or aluminum is used to make the connecting pins at the factory.

How to reset the camshaft position sensor?

The camshaft position sensor is one of the most common causes of a check engine light. In order to reset the code and clear the warning, you’ll need to disconnect the battery for about 10 minutes to reset everything. After 10 minutes, reconnect your battery and see if the light turns off on its own. If it doesn’t, try starting your car and see if that solves the issue.

If not, unplug the sensor again and wait another 10 minutes before trying again. Hopefully, this will resolve any issues.

Do camshaft sensors need to be programmed?

Programming the new camshaft position sensor is necessary because it needs to be calibrated with the engine computer. This can be done by an auto parts store or a mechanic. After the programming is complete, you’ll need to reset your check engine light in order for your car to pass emissions testing.