You can quickly and correctly test the crankshaft position (CKP) sensor on your 4.6L or 5.4L Ford pick up (SUV or automobile) with a multimeter set to Volts AC mode.

The Ford 4.6L and 5.4L crankshaft position sensors can be tested without a scan tool, though these days one is a need.

You will be guided step-by-step through the process in this lesson.

Important Guideline and Tips

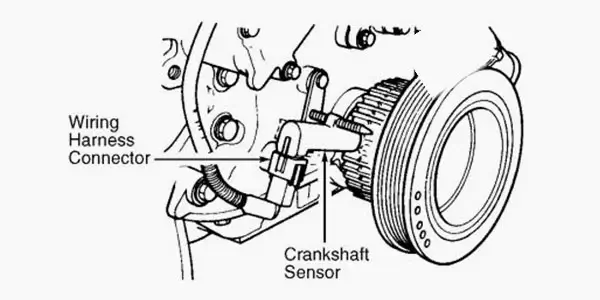

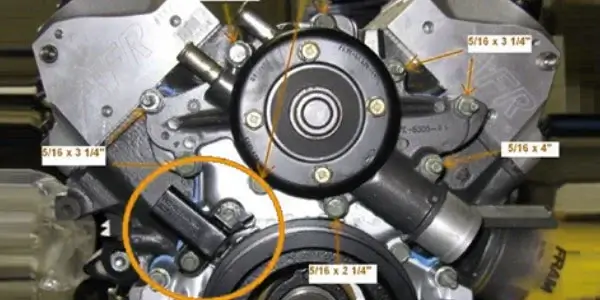

- Guideline 1: The timing chain cover is where the crankshaft position sensor is located. It is specifically located behind the air conditioning compressor and to the right (passenger side) of the crank pulley.

- Guideline 2: For this testing procedure, it is crucial that the battery in your Ford pickup or SUV is completely charged. The battery must have enough reserve power to crank the engine smoothly for many seconds.

- Guideline 3: To reach the CKP sensor, the car must be raised using a jack. To safely support the car off the ground, use a jack stand. It’s not a good idea to rely only on the jack. Safety glasses must be worn at all times to protect your eyes from flying objects. At all times, it is crucial to have a safety-conscious attitude.

- Guideline 4: A faulty CKP sensor results in a “no-spark no-start” situation. Therefore, you may confidently assume that the crankshaft position sensor is functional if you are seeing sparks from the ignition coil pack or the Coil-On-Plug ignition coils, and this particular test will not provide useful information.

Overview of Ford 5.4 Engine Crankshaft Position Sensor Symptoms

| Symptom | Description |

|---|---|

| Engine Misfires | Irregular engine firing causing rough idling and decreased power. |

| Stalling | Engine suddenly cuts off, often at low speeds or idle, due to inaccurate ignition timing. |

| Hard Starting | Difficulty in starting the engine, requiring multiple attempts. |

| Poor Acceleration | Sluggish response when pressing the gas pedal due to timing issues. |

| Hesitation | Momentary lack of power during acceleration, resembling a stumble. |

| Poor Fuel Efficiency | Decreased mileage due to inaccurate sensor data affecting fuel delivery. |

| Check Engine Light | Illumination of the warning light on the dashboard to indicate a problem. |

| Rough Idling | Engine runs unevenly while stationary, causing vibrations. |

| Sudden Loss of Power | Unexpected drop in engine power during driving, potentially unsafe. |

| Backfiring | Exhaust system pops or bangs, usually during deceleration, caused by improper ignition timing. |

Due to the variety of factors that can contribute to a ‘cranks but does not start’ situation, you may find additional diagnostic and troubleshooting insights in the following tutorial.

How Does The Crankshaft Position Sensor Work?

One of the most important parts for starting the engine in your Ford car (pickup, SUV, van) is the crankshaft position (CKP) sensor. Because it gives the PCM the signal it needs to start injecting gasoline and making sparks.

Here are some specifics of the crankshaft position sensor:

The 4.6L, 5.4L CKP sensor is a two wire variable reluctance sensor. What this means is that:

- Unlike a three-wire type Hall Effect sensor, it does not require an external power supply or a Ground source.

- The CKP sensor generates its own signal, which is an AC voltage signal.

Coil Pack Ignition System: If your specific Ford vehicle has an ignition control module (4.6L coil pack vehicles):

- The CKP sensor emits a CKP signal as soon as the engine cranks.

- The ignition control module receives the CKP sensor input directly.

- After the ignition control module receives the signal from the CKP sensor:

- The ignition module starts to activate both coil packs.

- Once the coil packs are activated, they start creating spark for each cylinder.

- The ignition module also creates a PIP signal which is sent to the PCM (Powertrain Control Module = Fuel Injection Computer).

- The PCM begins turning on the fuel injectors via the PIP (Profile Ignition Pickup) signal.

- Your Ford vehicle’s engine begins as a result of the PCM turning on the 8 fuel injectors and the coil packs producing spark for each cylinder.

Coil-On-Plug (COP) Ignition System: If your specific Ford vehicle does not use an ignition control module and is the Coil-On-Plug ignition system type:

- The PCM receives the signal from the crankshaft position sensor directly.

- After receiving the CKP sensor signal, the PCM:

-

- The PCM activates the Coil-On-Plug ignition coils to start sparking.

- The PCM activates the fuel injectors.

- The Ford vehicle (or pick-up, van, or SUV) engine starts as a result of each engine cylinder receiving fuel and ignition.

In the next section, I’ll go into some of the symptoms of a bad CKP sensor.

Ford 5.4 Crankshaft Position Sensor Symptoms

Before you proceed with the test, it’s crucial to remember an essential point:

In the event of a malfunctioning crankshaft position sensor (CKP sensor), the most evident symptom is an attempt to start the engine that results in cranking but no ignition and no fuel injection.

With a faulty crankshaft position sensor in your Ford 4.6L or 5.4L vehicle, you’ll also experience one of the subsequent indications:

- In vehicles equipped with coil packs: The ignition control module will fail to generate the PIP (Profile Ignition Pickup) signal, causing the PCM (Powertrain Control Module) to refrain from activating the fuel injectors.

- To confirm this, use a Noid light to examine fuel injector pulses.

- If you detect fuel injector pulses, the crankshaft position sensor is functioning correctly.

- In vehicles equipped with COP (Coil-On-Plug) coils: The PCM will not initiate the fuel injectors.

- You can confirm this by employing a Noid light to inspect fuel injector pulses.

- If fuel injector pulses are evident, the crankshaft position sensor is operating as expected.

- No ignition spark detected across any of the 8 engine cylinders.

- You can verify this by using a spark tester on each spark plug wire or COP coil.

- If there’s spark present (even on just one cylinder), the crankshaft position sensor is operating normally.

Alright, you’ve absorbed enough information – now let’s move on to the testing process!

TEST 1: Testing the Crankshaft Position Signal

The 4.6L and 5.4L Ford engines’ crankshaft position sensors are two-wire devices that are simple to test in AC Volts with a multimeter.

Remember that for this test to yield a reliable result, the battery must be completely charged. Why? Well, because the number of RPMs your engine is turning as it cranks determines the strength of the signal from the crankshaft position sensor that you’ll be monitoring with your multimeter.

The subsequent test procedures are predicated on your 4.6L or 5.4L pick-up (car, van, or SUV) cranking but not starting.

- Disconnect the electrical connector of the crankshaft position sensor.

- It’s necessary to remove portions of the plastic wire loom protector or any black electrical tape that shields the two wires of the crankshaft position (CKP) sensor.

- Reattach the connector to the crankshaft position sensor.

- Set your multimeter to Volts AC mode.

- Connect the red test lead of the multimeter to one of the two wires in the connector.

Note: Ensure that the multimeter test leads do not interfere with the crankshaft pulley or the serpentine drive belt, as the engine will be cranked in the following steps.

- Once everything is in place and you are a safe distance away from the engine, have your assistance start the engine while you keep an eye on the multimeter’s AC Volts readings.

- Be specific: the multimeter will not show a constant AC voltage; instead, it should show a fluctuating value of between 0.5 and 1 volts AC. Instead, only while the engine is revving will the readout continuously alternate between 0.5 Volts AC and 1 Volts AC.

Now, let’s evaluate your results and choose from the following scenarios that best align with your findings:

CASE 1: The multimeter indicated the specified AC voltage while the engine was being cranked. This outcome signifies that the crankshaft position (CKP) sensor is generating a reliable CKP signal and is functioning properly.

If you’ve confirmed that the CKP sensor is operational.

CASE 2: The multimeter did not display the specified AC voltage during engine cranking. This confirms that the crankshaft position sensor is defective and is the underlying cause of the ‘cranks but doesn’t start’ condition you’re encountering.

Frequently Asked Questions:

What is the role of the crankshaft position sensor in a Ford 5.4 engine?

The crankshaft position sensor in a Ford 5.4 engine monitors the rotational position of the crankshaft. This information is crucial for accurate ignition timing and fuel injection, ensuring optimal engine performance.

What are the common symptoms of a failing crankshaft position sensor in a Ford 5.4 engine?

Some common symptoms include intermittent stalling, rough idling, difficulty starting, poor fuel efficiency, and misfires. Additionally, the Check Engine Light may illuminate, and diagnostic trouble codes related to the sensor may be stored.

How does a faulty crankshaft position sensor affect engine performance?

A faulty sensor can lead to improper ignition timing and fuel injection, resulting in poor combustion, reduced power, and lower fuel efficiency. The engine might hesitate, stall, or run roughly.

Are there any specific diagnostic trouble codes associated with a malfunctioning crankshaft position sensor?

Yes, codes like P0335 (Crankshaft Position Sensor “A” Circuit Malfunction) and P0336 (Crankshaft Position Sensor “A” Circuit Range/Performance) may indicate issues with the sensor.

Can a failing crankshaft position sensor cause starting issues?

Yes, a failing sensor might cause difficulty starting the engine or extended cranking times, as the sensor provides critical data for the ignition system during startup.

How can I diagnose a faulty crankshaft position sensor in my Ford 5.4 engine?

Using an OBD-II scanner, you can retrieve diagnostic trouble codes related to the sensor. Additionally, you can perform a visual inspection of the sensor’s wiring and connections. For a more accurate diagnosis, consult a professional mechanic.

Can I drive my Ford 5.4 with a malfunctioning crankshaft position sensor?

It’s not recommended, as a faulty sensor can lead to unpredictable engine behavior and potential breakdowns. It’s advisable to address the issue promptly to avoid further damage.

How can I replace the crankshaft position sensor in a Ford 5.4 engine?

Replacing the sensor involves locating it near the crankshaft, disconnecting electrical connectors, removing fasteners, and carefully installing the new sensor. It’s recommended to consult your vehicle’s repair manual or seek professional help for this task.

Are there any preventive measures to extend the life of the crankshaft position sensor?

While the sensor is a wear-and-tear component, regular engine maintenance, including clean air filters and quality fuel, can contribute to its longevity. Addressing any engine issues promptly can also reduce stress on the sensor.

What should I do if I suspect a faulty crankshaft position sensor in my Ford 5.4 engine?

If you notice any symptoms or experience engine performance issues, it’s best to have your vehicle inspected by a qualified mechanic. They can diagnose the problem accurately and recommend appropriate solutions.