If your 4.3L, 5.0L, or 5.7L Vortec-equipped GM Pick Up or SUV has a defective crankshaft position sensor, this article will show you how to analyze and diagnose the problem.

Since a multimeter’s resistance test (Ohms) cannot be used to test the 3-wire crankshaft position (CKP) sensor, I’ve produced this article to demonstrate how to use a multimeter in Volts DC mode alone. You can use this highly accurate test to determine whether something is good or poor.

The ‘Applies To:’ box on the right and scrolling with the ‘Next > >’ button will show all of the applications since this crankshaft position sensor test article covers a wide range of GM years, makes, and models. Moreover, the data in

The ‘Applies To:’ box on the right and scrolling with the ‘Next > >’ button will show all of the applications since this crankshaft position sensor test article covers a wide range of GM years, makes, and models. Additionally, this article’s information is focused toward diagnosing and troubleshooting no-start, no-spark conditions as well as conditions where the engine cranks but does not start.

- SUGGESTION 1: If you turn the engine manually, the crank sensor test I’m going to demonstrate in this post is one of the most precise ways to test the crank sensor without an oscilloscope (and using only a multimeter). To turn the crankshaft pulley, you’ll need a 1/2 ratchet wrench and the proper socket.

- SUGGESTION 2: It’s crucial to unplug the fuel injector connector on the Spider before testing the crankshaft position sensor. When this connector is unplugged, the computer won’t be able to inject fuel into the engine.

How to Test the Crankshaft Position Sensor with the Right Equipment

You can test the crank sensor on your 4.3L, 5.0L, or 5.7L engine without purchasing any expensive tools.

Tools You’ll Need:

- Multimeter

-

- You can use a digital multimeter or an analog multimeter although the digital one is the preferred one.

- If you don’t have a multimeter or need to upgrade yours, check out my recommendation here: Buying A Digital Multimeter For Automotive Diagnostic Testing (at: easyautodiagnostics.com).

- 1/2 inch ratchet wrench

- Socket that will fit crankshaft pulley bolt.

- A helper.

Symptoms of a Bad Crankshaft Position Sensor

A malfunctioning crankshaft position sensor in a 5.7 Vortec engine can lead to a range of noticeable symptoms that impact overall engine performance. Some of the telltale signs include:

- Stalling or Difficult Starting: A malfunctioning crankshaft position sensor might result in sporadic stalling, rough idling, or problems starting the engine. This happens as a result of the sensor’s vital role in determining the timing of the fuel injection and ignition.

- Misfires: When the sensor fails to give the engine control module (ECM) precise timing data, misfires may happen irregularly or often. Reduced power production and incorrect fuel combustion are the results of this.

- Reduced Fuel Efficiency: Improper fuel injection can happen as a result of incorrect timing information, which results in inefficient combustion. Reduced fuel efficiency and higher fuel consumption are two examples of this inefficiency.

- Loss of Power: Incorrect ignition timing brought on by a faulty sensor may result in a reduction in engine power. Sluggish acceleration and poorer overall performance may result from this.

- Check Engine Light (CEL): A malfunctioning crankshaft position sensor is likely to trigger the check engine light on your vehicle’s dashboard. Retrieving the diagnostic trouble codes (DTCs) can help pinpoint the issue.

- Erratic Tachometer Reading: The tachometer, which indicates engine RPM, might exhibit erratic behavior or remain at zero even when the engine is running, indicating a problem with the sensor.

- Engine Hesitation or Surging: Inconsistent timing data can result in engine hesitation, where the vehicle momentarily loses power during acceleration. Conversely, engine surges may occur due to abrupt changes in timing.

- Rough Running: A malfunctioning sensor can cause the engine to run roughly or unevenly, with noticeable vibrations throughout the vehicle.

- Intermittent Cutting Out: The engine may cut out or die unexpectedly while driving, especially at low speeds, due to the sensor’s inability to provide accurate timing information.

- Transmission Issues: Timing inaccuracies can affect the transmission’s shift points and overall performance, leading to jerky or delayed gear changes.

These above are general symptoms but according to statistics 5.7 vortec crankshaft sensor most occurred symptoms listed below.

- The ignition coil won’t ignite.

- The ignition system won’t produce a spark.

- None of the spark plug wires are producing a spark.

- A triggering signal won’t reach the ignition control module, and without it, the module won’t turn the ignition coil ON and OFF to create spark.

- The fuel injectors will not be pulsed by the PCM (Powertrain Control Module; a fuel injection computer).

- After the initial priming voltage the PCM provides to the fuel pump when you turn the key to the ON position and then to the Start position, the PCM won’t turn on the fuel pump.

- When the crank sensor malfunctions, the PCM typically does not establish a unique faulty crankshaft position sensor diagnostic trouble code (DTC). But, every now and then it does, and when it does you’ll get:

- P0336 CKP Sensor Circuit Performance.

- P0337 CKP Sensor Circuit Low Frequency Code.

- P0338 CKP Sensor Circuit High Frequency Code.

- P0339 CKP Sensor Circuit Intermittent.

How the Crankshaft Position Sensor Works

The electronic control system of a modern internal combustion engine depends heavily on the crankshaft position sensor (CKP sensor). It is essential in determining the timing of the fuel injection and ignition on the engine. The crankshaft position sensor operates as follows:

Your 4.3, 5.0, or 5.7 liter GM Vortec engine’s crankshaft position sensor is a Hall Effect type sensor, which simply means that it requires electricity and a ground source in order to generate a signal.

This signal, which is an ON/OFF voltage signal (in DC Volts), is produced by the crank sensor.

In a nutshell, the 4.3L, 5.0L, and 5.7L Chevrolet or GMC (or Olds, Cadillac) pickup or SUV’s crankshaft position sensor functions as follows:

- The crank sensor receives 12 volts on circuit A and ground on circuit B when you turn the key and start cranking the engine.

- It starts to rotate when a circular “target wheel” mounted to the front of the crankshaft is positioned above and close to the crank sensor.

- The crank sensor starts to get activated as the “teeth” of this target wheel pass by it, producing an of/OFF pulse.

- A tooth from the target wheel must travel directly over the sensor in order for it to turn ON and generate and deliver a 5 volt DC pulse.

- OFF is when that same tooth passes completely away from the crank sensor, which causes the sensor to drop the voltage down to 0 Volts.

- The PCM uses these ON/OFF 5 Volt pulses to start activating the ignition control module and a host of other things to get your vehicle started.

- The most important thing to know about the crank sensor is that if it goes bad, your GM pickup or SUV will ‘crank but not start’ due to a lack of spark and fuel injection.

The only method for your multimeter to detect these ON/OFF voltage pulses is for you to manually turn the crankshaft pulley as instructed in my crankshaft position sensor test instructions. This type of test result is less reliable since using the starter motor averages out these pulses on the multimeter.

In conclusion, the crankshaft position sensor keeps track of the crankshaft’s rotation and sends crucial information to the engine control module (ECM), enabling perfect ignition and fuel injection timing. Maintaining effective engine operation, power delivery, and overall performance depends on precise timing coordination.

TEST 1: Testing the CKP Signal with a Multimeter

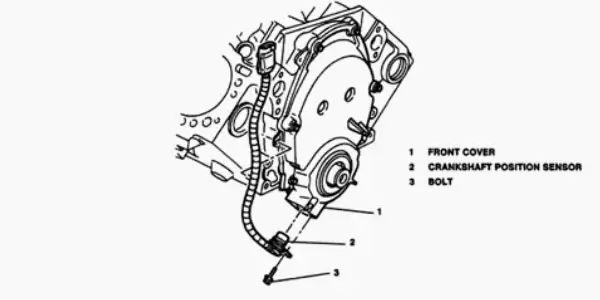

The engine timing chain cover’s bottom (passenger-side) housing houses the crankshaft position sensor. You must first check to see if there is a crank signal coming from the crank sensor.

This simple yet precise test will confirm the CKP sensor’s functionality. However, keep in mind that this accuracy is achieved by measuring the crank sensor signal with a multimeter and turning the engine manually by hand, as doing so with the starter motor would not produce the same results (unless you use an oscilloscope). I realize that I’m starting to sound like a broken record at this point.

NOTE: The crankshaft position sensor must remain connected to its electrical connector to read the CKP signal. You’ll need to use a back probe on the connector or a wire piercing probe on the wire.

OK, here’s the test:

- Lift the front of the pickup or SUV, then jack stands it down. Additionally, you will be able to gently crank the engine by hand using a 1/2 ratchet and the proper socket thanks to this.

- Turn off the gasoline system. Disconnecting the Spider fuel injector connector is one way to achieve this.

This is crucial! As you conduct the crank sensor test, you’ll prevent the car from possibly starting by turning off the gasoline injectors.

- Switch off the ignition. Simply detaching the ignition coil or ignition control module will enable you to achieve this. This will stop sparks from being produced by the ignition system.

- Using the proper equipment, such as a wire-piercing probe, attach the red multimeter test lead to the wire marked with the letter C in the above photo.

The CKP sensor signal is sent to the PCM via the wire (circuit) designated with the letter C.

- Connect the black multimeter test lead to the battery negative (-) terminal.

If you choose to connect the black multimeter test lead to a Ground point under the car, make sure the location is spotless and free of rust.

- Start the engine, but don’t turn the key to the ON (RUN) position.

- Put the Volts DC mode on your multimeter.

- Use a 1/2 inch ratchet and a socket on the crankshaft pulley to manually turn the engine in the clockwise direction.

- As you turn the crankshaft pulley, an ON/OFF voltage signal will be registered by your multimeter.

When the multimeter reads 5 Volts DC, it is ON, and when it reads 0 Volts (0.1 Volts equals 0 Volts), it is OFF.

Let’s analyze your Crank Sensor Signal Test results:

- CASE 1: As you cranked the engine with the ratchet, the multimeter recorded the ON/OFF voltage. This test result is accurate and shows that the crank sensor is producing a CKP signal and working properly.

Since the previous two tests in this article verify that the crankshaft position (CKP) sensor is receiving power and Ground, no additional testing is necessary. Your test demonstrates that the CKP sensor is producing a signal, proving that it is also receiving power and ground.

- CASE 2: When you turned the engine with the ratchet, the multimeter DIDN’T record the ON/OFF voltage signal. This test result typically shows that the crankshaft position sensor has to be replaced since it is damaged. Approximately 90% of the time, this is accurate, but I advise that you double-check to make sure the sensor is also receiving power and ground.

TEST 2: Verifying That The CKP Sensor Has Power

Your 4.3L, 5.0L, or 5.7L equipped GM vehicle’s crankshaft position sensor need power to operate, just like any other electrical equipment. When you flip the key to the ON position, the crank sensor is immediately connected to this power, which comes in the form of 12 Volts DC.

With the aid of this test, you can determine whether the sensor is receiving power or not. You’ll use your multimeter, just like in the previous test, to confirm this voltage signal.

The test steps are as follows:

- Set the multimeter to the DC voltage mode.

- Detach the electrical connector from the crankshaft position sensor.

- Attach the red test lead of the multimeter to the wire labeled as “A” in the image.

- Connect the black test lead of the multimeter to the negative (-) terminal of the battery.

- Turn the ignition key to the ON position without starting the engine.

- Your multimeter will indicate a reading between 10 and 12 Volts.

Now, let’s take a look at what those voltage readings (or lack of) mean:

Test 1: The multimeter registered 10 to 12 Volts when the ignition was switched ON. This outcome indicates the correct test result and verifies the power supply to the crankshaft position (CKP) sensor.

The subsequent test involves confirming that the CKP sensor has a proper connection to Ground. Proceed to: TEST 3: Verifying Ground Connection for the CKP Sensor.

Test 2: When the ignition was turned ON, the multimeter did not display 10 to 12 Volts. This outcome suggests that the ignition module is not providing power to the crank sensor.

This outcome eliminates the CKP sensor as the cause of the ‘cranks but doesn’t start’ issue you’re addressing. Since the crank sensor cannot generate a signal without these 12 Volts, this finding rules it out as the source of the problem.

Power originates from the ECM fuse located in the instrument panel fuse box. Verify whether the fuse has blown.

TEST 3: Verifying Ground Connection for the CKP Sensor

The 3-wire crankshaft position sensor maintains its distinct Ground path, established by the circuit (wire) designated with the letter B in the provided image.

Various methods exist to examine Ground in any given circuit. However, utmost caution is essential, as the fuel injection computer internally supplies this Ground path. Accidentally or intentionally shorting this circuit to 12 Volts from the battery will result in damage to the computer.

Here’s the procedure:

- Set the multimeter to Volts DC mode.

- Disconnect the crankshaft position sensor from its electrical connector.

- Attach the black test lead of the multimeter to the wire marked with the letter B in the image.

- Connect the red test lead of the multimeter to the positive (+) terminal of the battery.

- Turn the ignition key to ON without cranking the engine.

- The multimeter should show a reading of 10 to 12 Volts DC.

Now, let’s delve into the implications of these voltage readings or their absence:

- CASE 1: The multimeter displayed 10 to 12 Volts when the ignition was turned ON. This accurate result confirms a proper Ground path from the fuel injection computer to the crank sensor.

Considering that in TEST 1, you did not receive the 5 Volt ON/OFF signal and in TEST 2, your multimeter did indicate 12 Volts, you can confidently conclude that the CKP sensor is malfunctioning. Replacing the CKP sensor will effectively resolve the ‘no-start no-spark’ issue afflicting your vehicle.

- CASE 2: The multimeter did not show 12 Volts when the ignition was switched ON. This outcome signifies that the fuel injection computer is not providing a Ground path for the crank sensor.

This result exonerates the CKP sensor from causing the ‘cranks but doesn’t start’ dilemma. Without a functional Ground path, the crank sensor cannot generate a signal.

It’s exceedingly uncommon for an issue to arise within this circuit; personally, I have never encountered it. If this outcome aligns with your findings, your next step involves inspecting for any open-circuit problems within the wiring connecting the fuel injection computer and the crank sensor.

Check out the Real Discussion:

Real Discussion 1:

I don’t detect any severe play when using the method mentioned above to check the timing chain. 5 or less degrees of play. Now that the truck is back at home and not stuck in the grocery store parking lot, I checked the compression again, and I’m getting close to 90 psi on all cylinders. I think I might have forgotten to keep the gas pedal depressed and probably didn’t blast it for long enough in the parking lot; I guess I was so anxious about flashing my booty to all the passing drivers. I’m seeing much more regular compression readings now that I’ve standardized my methodology for every cylinder. I’m not too concerned about these being a little low since I haven’t warmed up the engine, but then it won’t start on my subsequent effort.

Real Discussion 2:

I’m at a loss with the 1997 Vortec 350. I was using it to drive around town and complete my usual errands. When I reached my final stop for the day, I finished up and left the parking lot, leaving me stranded. I started the truck and drove it approximately 200 feet before the engine stopped suddenly and quietly. When I tried to restart it, I was met with sounds of the engine trying to start but not in a good way at all.

The precise symptoms I’m experiencing are listed below:

- No running, just free cranking and spitting

- A big flame is produced by the throttle body when ether/starter fluid is used, and a backfire is caused by gas directly in the intake.

Check out more real life discussion. Related to gm vehicles and specifically 5.7 Vortec Crankshaft Position Sensor Symptoms.

You might want to see this:

- What Scanner Can Relearn Crankshaft Position Sensor

- What to Do After Replacing Crankshaft Sensor

- Will Disconnecting Battery Reset Crankshaft Sensor – Guide

Frequently Asked Questions:

How do you test a GM crankshaft position sensor?

Refer to above, a complete guide to how to test CKS.

What is the 7 symptoms of a bad crankshaft position sensor?

- Engine Stalling or Hard Starting

- Misfires and Rough Idling

- Reduced Fuel Efficiency

- Loss of Engine Power

- Check Engine Light (CEL) Illumination

- Erratic Tachometer Reading

- Intermittent Cutting Out or Hesitation

Does crank sensor control fuel pump?

No, the fuel pump isn’t specifically under the control of the crankshaft position sensor (CKP sensor). However, it gives the engine control module (ECM) important information for timing the ignition and fuel injection, which indirectly affects the operation of the fuel pump by guaranteeing appropriate combustion and engine performance. Based on the needs of the engine, the ECM decides whether to activate the fuel pump using a variety of inputs, including data from the CKP sensor.

Will a bad crankshaft position sensor always throw a code?

No, a bad crankshaft position sensor may not always trigger a diagnostic trouble code (DTC). While a malfunctioning sensor often leads to inconsistent engine performance, the absence of a code can occur if the sensor’s signal remains within a tolerable range for the engine control module (ECM). However, diagnosing symptoms and using testing tools can help identify sensor issues even without a DTC.

What codes will a bad crankshaft sensor cause?

A bad crankshaft position sensor can trigger codes like P0335 (Crankshaft Position Sensor “A” Circuit) or P0336 (Crankshaft Position Sensor “A” Circuit Range/Performance).

These codes indicate problems with the CKP sensor’s signal, leading to issues with ignition timing and fuel injection synchronization. Engine misfires, stalling, and poor performance may result from these codes.