The Allison 10L1000 10-speed gearbox is the heavy-duty automatic transmission used in Chevrolet Silverado and GMC Sierra HD vehicles. That means it’s a strong, albeit complicated, gearbox capable of handling the additional load imposed by the Duramax diesel engine. It boasts the most relative torque capacity of any full-size vehicle ever produced. However, issues have arisen, which we will discuss presently.

The 10L1000 transmission was introduced by GM with 2020 trucks. From 2001 until 2019, it replaced the Allison 1000 and 2000 six-speed automatic transmissions in GM Duramax trucks. The 10-speed transmission was developed together by Ford and GM. The 10L1000 and Ford’s TorqShift 10R140 are nearly identical internally. Parts can be swapped between the two.

The majority of these issues are caused by aftermarket applications. To customize and strengthen up their GM heavy-duty vehicles, many heavy-duty truck owners choose tuning adjustments or higher tyre sizes. Many of these concerns will arise at that time.

10 Speed Allison Transmission Duramax Problems

Problem -1

Faulty Torque Converter Lockup Mechanism

The issue with this lockup mechanism happens when people either:

- Increase tire size without a regear

- Exceed 500HP often

- Tow extremely heavy loads

In detail:

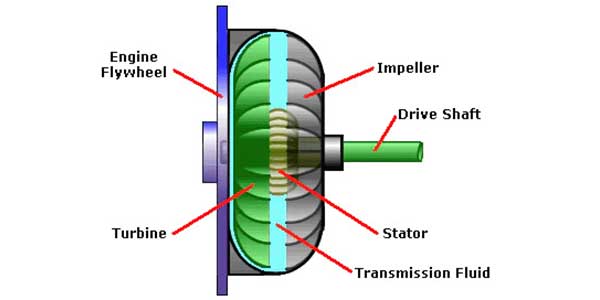

If this transmission has an Achilles’ heel, it is the woefully inadequate OEM torque converter. Because there is so much good and so much negative, we have broken this into several pieces. The issue here isn’t designed; rather, it’s a funhouse mirror version of Ford’s 6R140 Torque Converter’s locking mechanism. The lockup mechanism on Ford’s 6R140 was outstanding in that it locked up towards the stator rather than the flex plate.

For general dependability, heat management, and oil coupling, extremely heavy duty transmissions such as the 10L1000, 6R140, and AS69RC use converters with reversed or “backwards” locking mechanisms. This development in engineering is a healthy improvement in durability, but it does not make the device faultless.

The reality is that, although testing is difficult owing to factors, the torque capability of this locking mechanism appears to die at nearly any power level over factory, OR when tire size is considerably increased without a proper regear. Trucks with more than 500 horsepower or that want to pull particularly big loads are unlikely to survive. For individuals who are concerned about this issue, we do offer two distinct Billet Multi-Friction Torque Converters.

Problem – 2

The Stator

The stator, the component inside the torque converter that governs stall speed, is extremely fragile and leads to heat management issues. This is a shortcoming that Ford, and especially GM/Allison, have been tormented within the diesel world for years. Despite the fact that Dodge converters are poorer, they feature the most powerful stators that we have tested in factory form. As a result, anyone wishing to improve this torque converter must modify the stator.

The answer is multifaceted; the first step is to discover a stronger material from which to make the stator. As a result, CNC machined and, in certain cases, billet stators (depending on the application) are utilized to prevent the common gyration, cracking, or yaw that geometrically impair this item’s capacity to perform consistently.

To put it simply, any 10L1000 or 10R140 torque converter with an unaltered OEM stator is far more likely to fail. As a result, none of our 10L1000 Torque Converters employ a factory stator. We like to precision manufacture the converter’s stator, which gives us complete control over stall speed.

Problem – 3

Functional Issues Due To Increased Power

This leads us to the next item, the friction factors. As previously noted, this is an excellent idea; however, the diesel community is not unfamiliar with tuning platforms such as EFI Live or EZ Lynk being utilized to improve efficiency, power output, and functionality. As a result, this converter is frequently required to resist greater power than it was originally designed to bear, necessitating the intervention of the aftermarket.

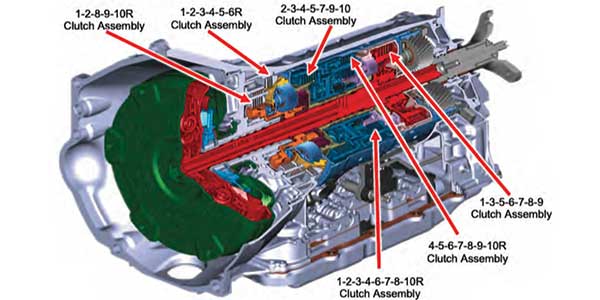

As a result, any client considering tuning this truck should be aware that the clutch and steel stack-ups inside the transmission are normally only enough for the amount of torque produced by the truck from the factory and nothing more. This involves the use of billet pistons, billet reaction plates, modified clutches, and steels of enough dimension and quality to meet the expectations of the customer.

Lastly, on the topic of friction elements and torque converters as well as how they are challenged by added power, the 10L1000 and 10R140 have a unique ability to achieve lockup as early as 1st gear to help regulate heat. Fluid coupling produces about 70% of the heat generated by this transmission depending on barometrics, stall speed, drivetrain and other thermostatic factors. This stated, it is imperative that a torque converter is designed with the priorities of longevity, heat management and power capacity.

Problem #4 –

The “E” Clutch Hub

This is a difficult one. The “E” Clutch is located deep inside the transmission and is active in first, third, fifth, sixth, seventh, eighth, and ninth gear, making it the most utilized and abused clutch in the system by any reasonable criteria. This clutch is highlighted in red in the diagram above, closer to the back of the transmission.

The aluminum castings used to create components like these, like with other Ford TorqShift designs dating back to the late 1980s, are prone to severe wear and catastrophic damage. In reality, the bulk of the 10L1000s and 10R140s we’ve observed with increased power show significant wear to this exact component.

In short This “E” clutch hub is made of aluminum for its lightweight properties. Being made of aluminum means it will barely make it through the warranty under normal conditions.

Solution:

A custom machined steel “E” Clutch Hub addresses both of these issues at the same time by changing to a stronger material and improving the design to enhance torque capacity and heat dissipation through extra frictions and steels.

When both are used in the same gearbox, the result is smooth, crisp, and predictable shifts that can be relied on for years to come, regardless of what’s behind you or in front of you. As a result, this is an essential component of a well-constructed 10L1000 transmission.

Problem – 5

The OEM Oil Pan

This is a minor flaw, but it is worth mentioning. Like the rest of the transmission industry, these pans are composed of stamped metal that is heated and then naturally cooled to keep its form. This is a concern for a variety of reasons:

- Because there is no precise flattened surface on the pan’s side, it does not allow for a suitable mating surface where the pan mates to the case.

- The pan is extremely thin and cannot handle any kind of rough use. Factory pans should be avoided by off-roaders.

- The pan is far too small; this gearbox requires more fluid to function at top performance and cool temperatures; the original pan prevents this by preventing a potentially safe increase in oil. This causes the transmission to operate hotter than it should, reducing the lifespan of the transmission’s friction elements and torque converter.

- Because the pan lacks adequate surface area to efficiently exhaust heat, heat is directed elsewhere. This is due to the fact that heat is a type of energy. Increases in the surface area improve a metal’s capacity to discharge heat into its surroundings.

Problem – 6

The High-Pressure Oil Pump

The 10L1000 transmission’s oil pump is similar to late-model TorqShifts in that its impeller hub (seen below) is splined to match directly into the pump. The torque converter impeller hub is the component on the back of the converter that sits in the pump and spins the central pump gear, which provides pressure. This is intended to distribute torque stress more evenly over the pump and impeller hub, reducing failures.

This is a benefit, but an inferior converter and clutch stack-ups compel the pump to consume clutch material and steel particles on a frequent basis. As a result, in a factory gearbox, this pump will have a decreased lifespan owing to indirect influences.

Solution:

Stronger clutch packs that are suited for the task, rather than trying to meet their requirements, contribute to the Allison 10L1000’s far longer-lasting high-pressure oil pump.

Problem – 7

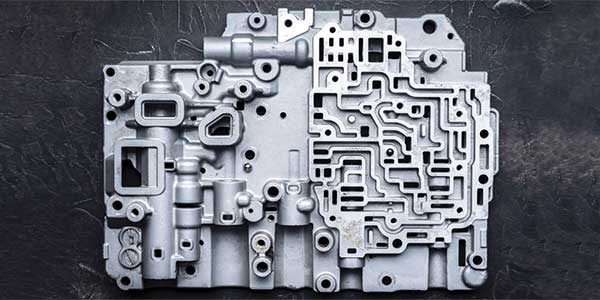

The Valve Body

In the past, Ford has been known to design devices like this using ZF-based valve bodies. This time, though, it looks to be a more private design. The valve body in this gearbox experiences the same wear issues as the high-pressure oil pump. However, the link between the valve body and the transmission’s electronics complicates matters.

There is no regenerative solution with this gearbox once a valve body has begun to wear. This valve body suffers from galvanic wear, which begins the day it leaves the dealership.

Solution:

As with the pump, the key here is to ensure that the valve body is given the necessary pre-requisites for success from the start; a correctly designed transmission that will not shed particles of matter via these delicate hydraulic components.

Problem – 8

Other Signs of GM Transmission Problems

Worn or slipping transmissions have many warning signs. A damaged transmission creates a dangerous situation for you and for other drivers. Be aware of these signs:

- Slow or no response

- Leaks and puddles under your car

- Warning lights on your dash

- Grinding or clunking noises

- Shuddering

Conclusion

You might attempt a couple of different remedies to your GM transmission difficulties. You could replace the transmission and hope it doesn’t happen again, or you could have a bespoke transmission repair or regear, or you could buy a different truck.

None of them are good options. If GM accepted responsibility, they could issue a recall and redesign to address the flaws.

More:

What Causes a Transmission Control Module to Fail

Symptoms of Bad Clutch in Automatic Transmission

How long does the 10-speed Transmission Last?

The good news is that 10-speed gearbox will typically last 200,000 kilometres. That means you’ll have plenty of time to enjoy it before having to replace it.

However, there are a few things you should keep in mind if you want your 10-speed transmission to endure that long. First and foremost, remember to replace your oil. This can assist keep your engine parts properly lubricated and prevent dirt from accumulating in the engine.

Second, ensure sure your tires are constantly properly inflated—and check them frequently! Finally, try to avoid driving at high speeds whenever possible—this will help keep your transmission in good condition.

How to Make the 10-Speed Transmission Last Longer

- Transmission Routine Changes in fluid.

- Before changing gears.

- Make sure the transmission fluid is at the proper level.